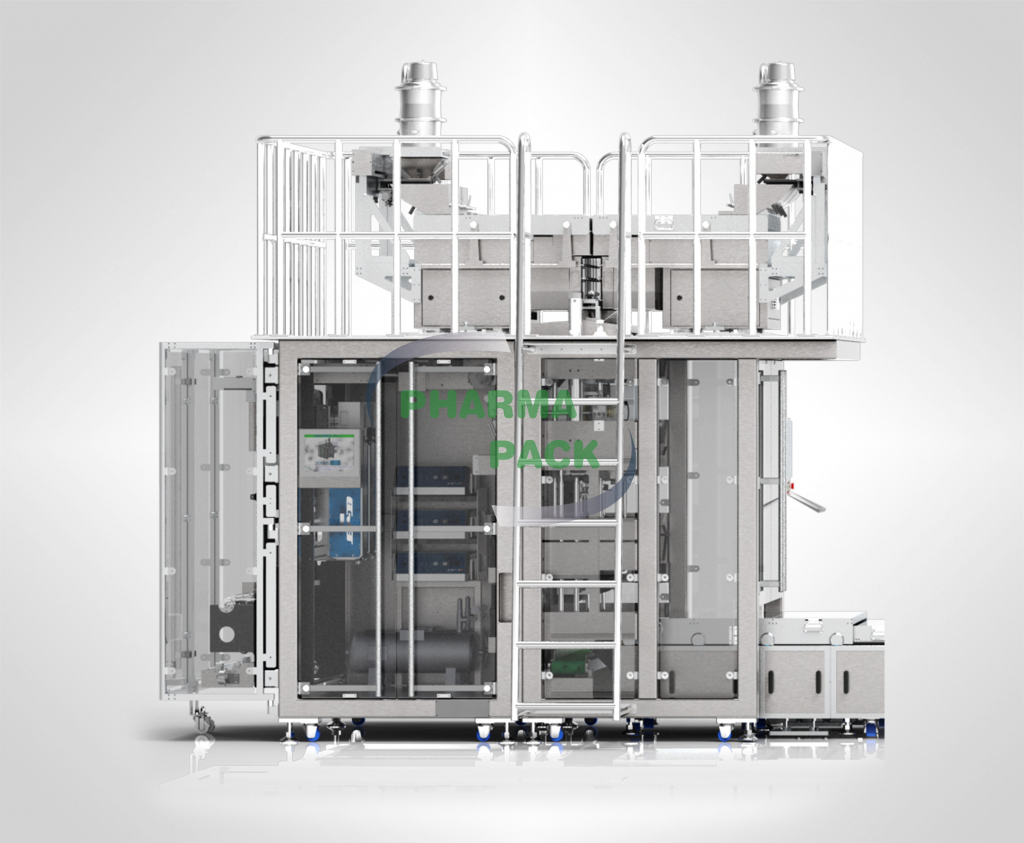

One of Pharmapack’s most notable products, the ALFVS-12S tablet counting filling machine, has an advanced dust recovery system that greatly improves the overall packaging process by minimizing material waste and streamlining production. Pharmapack is a leader in innovation in the pharmaceutical manufacturing industry, renowned for its cutting-edge equipment designed to enhance operational efficiency.

Enhancing Cleanliness and Safety

The dust recovery system integrated into the ALFVS-12S tablet counting filling machine plays a crucial role in maintaining a clean working environment. It utilizes a vacuum mechanism to effectively capture and recover dusty materials generated during the packaging process. This feature not only prevents dust from contaminating the products but also reduces the risk of cross-contamination, a critical factor in pharmaceutical settings. By ensuring cleanliness, the machine upholds the highest safety standards, which is essential for pharmaceutical manufacturers.

Boosting Production Efficiency

In addition to cleanliness, the dust recovery system enhances the efficiency of the tablet counting filling machine. Dust can cause material jams and disrupt the filling process, leading to production delays and increased downtime. By minimizing dust and improving material flow, the ALFVS-12S ensures a continuous and uninterrupted operation. The adjustable angle and timing settings for dust extraction allow operators to optimize the system according to their production needs, further enhancing efficiency and consistency.

Conclusion

In conclusion, the ALFVS-12S tablet counting filling machine from Pharmapack exemplifies how advanced technology can bolster operations in the pharmaceutical industry. With its effective dust recovery system, it not only maintains a clean and safe working environment but also drives production efficiency. Thus, Pharmapack continues to provide essential solutions that empower medical companies and pharmaceutical manufacturers to achieve their operational goals.